-

AUSTRALIA, ENGLISH

- Contact

- Where to Buy

- Favourites

-

Looking for product documents?

Try our Document Finder

-

About Knauf

-

About Knauf

-

About Us

-

About Us

-

- Careers

- Code Of Conduct

- Supplier Information

-

-

Products

-

Products

-

Ceilings

-

Ceilings

- Acoustic Panels & Ceiling Tiles

ACOUSTIC PANELS & CEILING TILES

- Acoustic Suspension Systems

ACOUSTIC SUSPENSION SYSTEM

- Drywall Suspension Systems

DRYWALL SUSPENSION SYSTEM

- Stratopanel Ceiling System

STRATOPANEL® CEILING SYSTEM

-

-

Plasterboard

-

Plasterboard

- SHEETROCK® Plasterboard

SHEETROCK® Plasterboard

- Technical Boards

TECHNICAL Plasterboard

- Multi-Application Boards

Multi-Application Boards

- Water-Resistant Plasterboard

Water-Resistant Plasterboard

-

-

Finishes

-

Finishes

- Jointing Compounds

Jointing Compounds

- Speciality Plasters

Specialty Plasters

- Adhesives

Adhesives

- Primers

Primers

- Joint Tapes

Joint Tapes

-

-

Steel Framing

-

Steel Framing

- Rondo® Metal Components

Rondo® Metal Components

-

-

Cornice

-

Cornice

- SHEETROCK® Cove

SHEETROCK® Cove

- Decorative Cornice

Decorative Cornice

-

-

Cement Board

-

Cement Board

- Cement Board Indoor

Cement Board Indoor

- Cement Board Outdoor

Cement Board Outdoor

-

-

Insulation

-

Insulation

- Wall Batts

Wall Batts

- Ceiling Batts

Ceiling Batts

- Acoustic Range

Acoustic Range

- Ecose Technology

ECOSE® Technology

-

-

Plastering DIY

-

Plastering DIY

- DIY Cornice Adhesive

DIY Cornice Adhesive

- DIY Patching Plaster

DIY Patching Plaster

- Total Joint Finish

Total Joint Finish

- Stud Adhesive

Stud Adhesive

- Tools & Accessories

Tools & Accessories

-

-

-

Solutions

-

Solutions

-

Segment Solutions

-

Segment Solutions

- Wet Area Solutions for Architects

Wet Area Solutions

-

Wet Area Solutions

Water resistant plasterboard obtains its impressive water-resistant properties from a range of special ingredients added to the core of the board. Its moisture resistant core limits water wicking up the board causing damage to the board itself or the surface finish.

- Wet Area Solutions for Trade

Wet Area Solutions

-

Wet Area Solutions

Water resistant plasterboard obtains its impressive water-resistant properties from a range of special ingredients added to the core of the board. Its moisture resistant core limits water wicking up the board causing damage to the board itself or the surface finish.

- Health Care

Health Care

- Education

Education

- Bushfire Protection

Bushfire Protection

- Multi-Residential

Multi-Residential

-

-

Plasterboard Systems

-

Plasterboard Systems

- Systems+

Systems+

- CinemaZone® System

CinemaZone®

- Fireclad® System

Fireclad® Fire-rated External Wall System

- Firewall® System

Firewall® System

- IntRwall® System

IntRwall® System

- Multiframe™ System

Multiframe™ System

- NeighbourZone™ System

NeighbourZone™ System

- OutRwall® System

OutRwall® System

- Partiwall® System

Partiwall® Separating Wall System

- Quiet Living™ System

Quiet Living™ System

- Cross Laminated Timber Systems

-

-

Science

-

Science

- Acoustics

Acoustics

- Fire Performance

Fire Performance

- Seismic

Seismic

-

-

-

Inspiration

-

Inspiration

-

For Architects / Designers

-

For Architects / Designers

-

Knauf for Architects / Designers

We believe we can change the way buildings are designed, built and occupied by delivering innovations that help you work smarter, do more and build better.

-

-

For Builders / Installers

-

For Builders / Installers

-

Knauf for Builders / Installers

Proudly Supporting those who Build, every step of the way.

-

-

For Homeowners

-

For Homeowners

-

Knauf for Homeowners

Our plastering products, tools & accessories are designed for the home renovator/builder making minor alterations or repairs to plasterboard walls & ceilings.

-

-

-

Resources & Tools

-

Resources & Tools

-

Acoustic Ceilings e-Estimator

-

Acoustic Ceilings e-Estimator

-

- Plasterboard Installation Manual

- eSelector

- BIM WIZARD

- Partiwall Estimator

-

Systems+ Plasterboard Systems Guide

-

Systems+ Plasterboard Systems Guide

- FEATURES

- TRY IT FOR YOURSELF!

-

See All

-

- Document Finder

-

TecASSIST

-

TecASSIST™ - Knauf

-

-

CAD Finder

-

CAD Finder

-

-

Knauf Warranty

-

Knauf Warranty

- Knauf Warranty

-

See All

-

-

-

What's New

-

What's New

-

News And Promotions

-

News & Promotions – Knauf AU

- New Formula BaseCote™ Now Available

- September Stocktake Notice

- New 2024 Release of Systems+ Design Guide Now Available

- New Stratopanel Acoustic Performance Data

- Knauf Holiday Hours

-

See All

-

- Press

-

AUSTRALIA, ENGLISH

- Contact

- Where to Buy

- Favourites

- My Downloads

-

User Profile

User Profile

- Manage Profile

- Logout

-

Looking for product documents?

Try our Document Finder

SUWg4HBaYP13VYhuSncYIghttps://myaccount.knaufapac.com -

LIGHTING & DECORATING PLASTERBOARD

Most customers have an expectation of a perfectly flat, blemish-free plasterboard surface finish. In practice, however, such finish is impossible to achieve and all that can be realistically expected is the perception of flatness.

A major cause of dissatisfaction with plasterboard surfaces is, in fact, unfavourable lighting from internal or external sources.

Knauf has updated its popular Lighting and Decorating Plasterboard Guide to assist architects, interior designers, builders, plasterers and home renovators in achieving the desired wall and ceiling results.

Design Influences

There are many factors in modern building design that influence the overall appearance of walls and ceilings. Many of today’s homes have large open living areas with unbroken ceilings across adjoining rooms and, importantly, large windows and skylights. While providing the desired modern and spacious look, these features often create lighting conditions detrimental to the appearance of wall and ceiling surfaces.

It is important that surface finish expectations are based on what can be realistically achieved given the design features of the project, particularly when some design features are likely to magnify any minor surface irregularities.

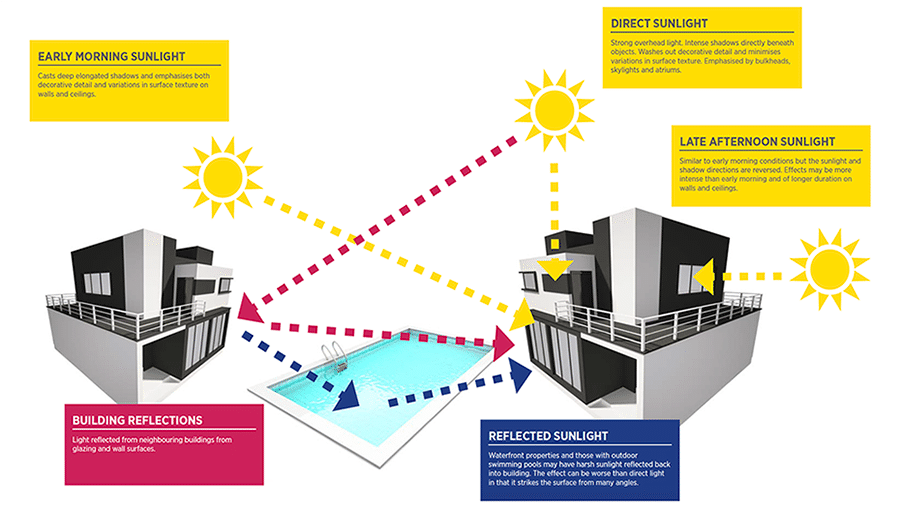

When considering the effects of building orientation and window size and positioning on appearance of wall and ceiling surfaces, one should be aware of the effects of external light at different times of the day.

Natural Lighting Influences

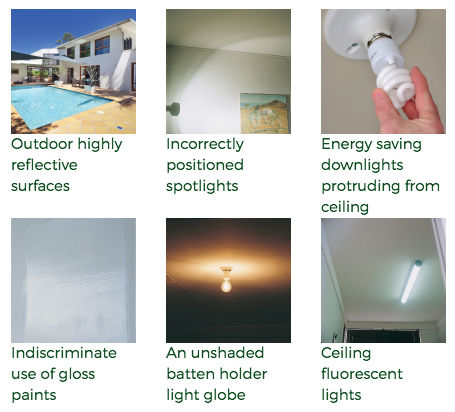

Examples of unfavourable lighting

Glancing Light

When architects, builders and home owners are considering what standard of finish is desired for plasterboard walls and ceilings, it is important to understand how the overall appearance is likely to be affected by glancing light.

Glancing light is the light that shines directly across the surface of a wall or ceiling.

Glancing light magnifies surface irregularities and can spoil the look of the highest quality surface finish.

Glancing Light

Critical instances of glancing light can occur when a single unshaded light source is fixed directly to the ceiling or wall, but also in rooms with windows up to ceiling height or adjacent to walls.

A particularly severe glancing light problem occurs when a surface-mounted fluorescent batten light fitting is placed parallel with the plastering joints. Resultant high intensity white light falling at a shallow angle will magnify any surface irregularities.

Incorrectly positioning a spotlight to highlight an object can also create a glancing light effect emphasising surface irregularities on walls and ceilings. Feature or spot lights should only light the featured object.

Lighting

Lighting is one of the most important elements in building design and can add that special finishing touch. One must be aware of the effects of glancing light when considering lighting types and positioning. Modern lighting solutions can help to balance illumination and shadow and to achieve a better outcome in a new home or commercial project.

Although the selection of light fittings is usually governed by taste and budget, it is wise to consider lighting effect on internal surfaces even before construction is commenced.

Large living areas, which are a feature of modern open plan designs, are the most severely affected by glancing light. Consideration should be given to illuminating such areas with general diffused light using downlights or spotlights, in combination with local accent lighting such as floor lamps, table lamps, etc.

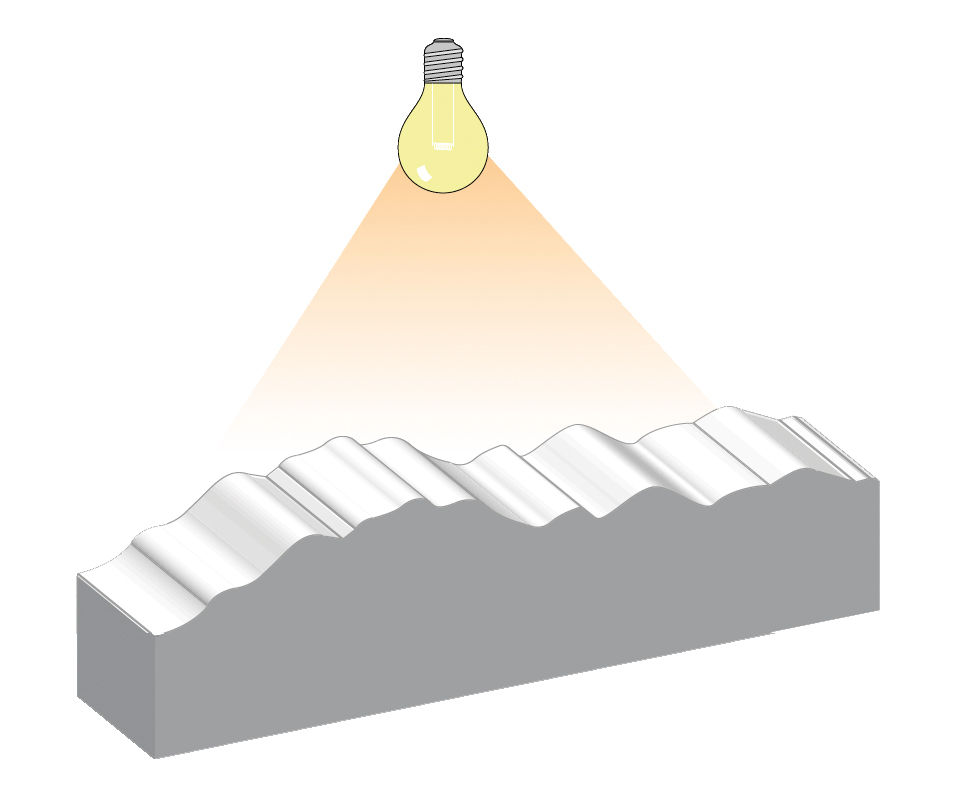

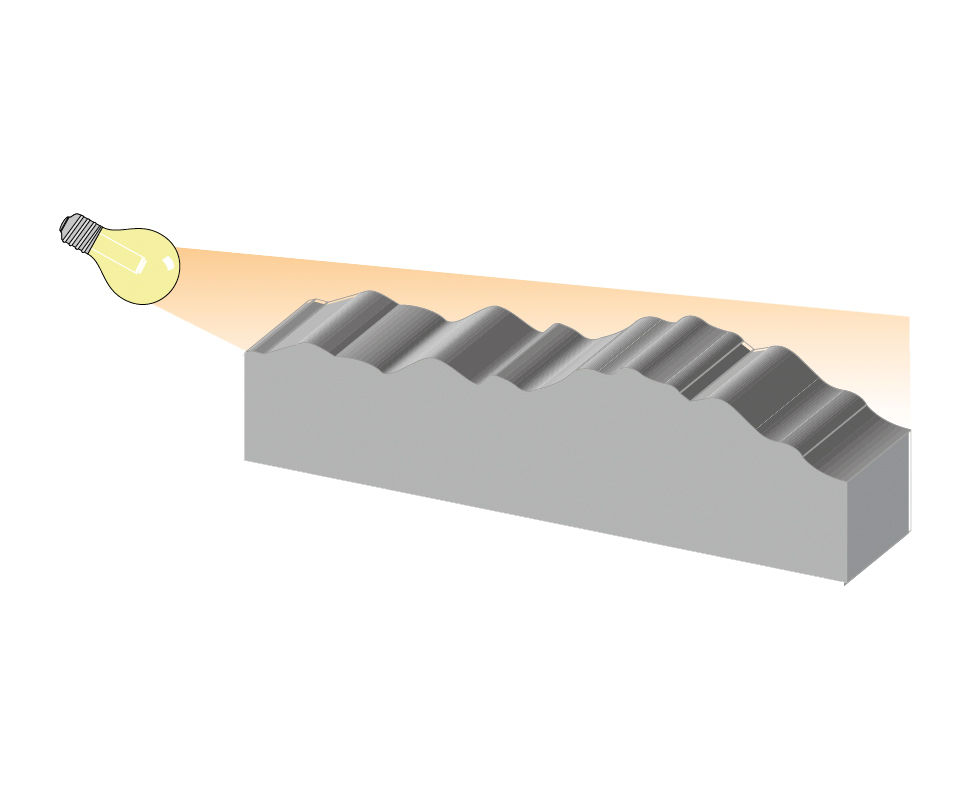

Favourable Lighting

Unfavourable Lighting

Favourable Lighting

Unfavourable Lighting

GLOSS/SHEEN PAINT FINISHES

Gloss and even semi-gloss paints will accentuate surface variations regardless of the direction of lighting or the viewing angle. Flat paints however, reflect light in a diffused form and thus mask surface variations.

As plasterboard’s paper surface has a different surface texture from hand applied jointing materials, this difference in texture can be accentuated by gloss paints.

Where gloss or impervious sheen paint finishes are desirable or mandatory for functional reasons (eg in kitchens, bathrooms and commercial food preparation areas), some loss of appearance can be expected, even when the work has been carried out to the highest level of workmanship.

LEVELS OF FINISH

DEFINITION

The term ‘level of finish’ applies to plasterboard linings prior to decoration.

AS/NZS 2589 ‘Gypsum linings – Application and finishing’ defines three levels of finish: Levels 3, 4 and 5. Level 4 is the default level of finish for plasterboard surfaces, unless otherwise specified.

It is essential that the level of finish is determined at the design stage since each level of finish has specific requirements for substrate tolerances and plasterboard installation, jointing and finishing. The desired level of finish may not be achieved unless all of these requirements are met through various stages of construction. For a full description of levels of finish refer to AS/NZS 2589.

Level 3

This level of finish is used in areas that do not require decoration or where finish is not important (for example, above ceilings or inside service shafts and the like).

Level 4

This is the default and generally accepted level of plasterboard finish.

Level 5

Level 5 finish should be used where gloss or semi-gloss paints are specified or where flat or low sheen paints will be exposed to critical lighting conditions. Level 5 finish is characterised by a parity of surface texture and porosity.

JOINT INSPECTION AND TOLERANCES

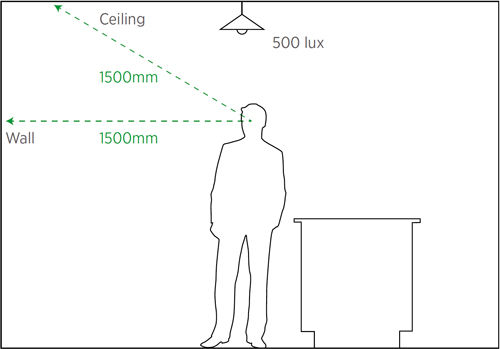

As outlined in AS/NZS 2589:2017 ‘Gypsum linings – Application and finishing’, a visual inspection of wall and ceiling surfaces should be carried out from a distance of 1.5m or greater, under normal lighting conditions.

Plasterboard surfaces should not be inspected under high intensity lighting or under glancing light conditions.

Allowable tolerances for plasterboard joint build-up are outlined in AS/NZS 2589:2017 ‘Gypsum linings – Application and finishing’.

Refer AS/NZS 2589 and the relevant industry publications for guidance on conducting plasterboard joint inspections.