-

PHILIPPINES, ENGLISH

- Contact

- Where to Buy

- Favourites

-

Looking for product documents?

Try our Document Finder

-

Who is Knauf

-

Who is Knauf

-

About Knauf

-

About Us

-

- Careers

-

Contact Us

-

Contact Us

-

- Code Of Conduct

- Supplier Code of Conduct

-

-

Products

-

Products

-

Wall

-

Wall

- Standard Gypsum Boards

Standard Gypsum Board

- Technical Gypsum Boards

Technical Gypsum Board

-

-

Ceilings

-

Ceilings

- Acoustic Panels & Ceiling Tiles

ACOUSTIC PANELS & CEILING TILES

- Vinyl Ceiling Tiles

VINYL CEILING TILES

-

-

Jointing and Finishing

-

Jointing and Finishing

- Premium Jointing

Premium Jointing

- Premium Premix

Premium Premix

- Paper Joint Tape

Paper Joint Tape

- Premium Cornice

Premium Cornice

- Premium Casting

Premium Casting

-

Technical Boards

-

-

Solutions

-

Solutions

-

Commercial

-

Commercial

- Health Care

Health Care

- Education

Education

- Offices

Offices

- Hotel

Hotel

- Retail

Retail

- Entertainment

Entertainment

-

-

Residential

-

Residential

- New Built Residential

New Built Residential

- Repair, Maintainance, Improvement

Repair, Maintainance, Improvement

-

-

USG BORAL EASYFINISH®

-

USG BORAL EASYFINISH®

- USG Boral EasyFinish® Bond System

USG Boral EasyFinish® Bond System

-

USG Boral EasyFinish® Bond System

This system is also known as the “scoop” system, a cement plaster replacement system that is cost efficient, easy to install, and minimizes the chances of cracks.

- USB Boral EasyFinish® Frame System

USB Boral EasyFinish® Frame System

-

USB Boral EasyFinish® Frame System

This system uses metal framing applied as a wall lining, making it especially suitable for reinforced concrete walls or block walls with severe irregularities. It also improves acoustic performance while allowing services to be placed in its cavity.

- USG Boral EasyFinish® Solid System

USG Boral EasyFinish® Solid System

-

USG Boral EasyFinish® Solid System

This system offers two different application methods. EasyTrowel® Application and EasyScoop® Application. These tools provide an easy way to apply the bonding compound in the right thickness, or an innovative solution that eliminates the need to use a mortar-and-sand mix for plastering.

-

-

-

Inspiration

-

Inspiration

-

-

Resources & Tools

-

Resources & Tools

-

CAD Finder

-

CAD Finder | Knauf Philippines

-

- Document Finder

- Lighting & Decoration Guide

-

Acoustic Ceilings e-Estimator

-

Acoustic Ceilings e-Estimator

-

-

plasterboard-materials-estimator

-

Plasterboard Materials Estimator

-

-

-

What's New

-

PHILIPPINES, ENGLISH

- Contact

- Where to Buy

- Favourites

- My Downloads

-

User Profile

User Profile

- Manage Profile

- Logout

-

Looking for product documents?

Try our Document Finder

SUWg4HBaYP13VYhuSncYIghttps://myaccount.knaufapac.com

480 Queen St, Brisbane - SHEETROCK®

Main Products Used

SHEETROCK® Ceiling Board

People Involved

Architect BVN Donovan Hill

Builder Grocon

Contractor NAC Northern Australian Contracting

Project Scope

USG Boral 13mm SHEETROCK® Plasterboard used on internal ceilings in 34 level commercial tower.

Special Factors

“The key issues for us as the head contractor when selecting materials for use on site include: safety; cost; time; speed of installation and availability of product; ease of handling/transporting to site and while on-site; and environmental benefits of products as the project is chasing a 6-star Green Star as-built rating”

Project Cost

$200 million

Need help with a similar project?

SHEETROCK® USED IN ICONIC BRISBANE OFFICE TOWER

USG Boral’s patented SHEETROCK® Plasterboard is USG Boral’s newest engineered lightweight gypsum; an alternative to its Standard 13mm plasterboard. SHEETROCK® Plasterboard is used in the plasterboard margin area and around the lift cores on all 34 floors of this iconic building in the heart of Brisbane.

-

480 Queen Street, Brisbane - SHEETROCK®

Grocon, the head contractor for the project, were happy to listen to the recommendations of Northern Australian Contracting (NAC), the plasterboard contractor, as to how they could optimise the specifications provided for the project.

“The key issues for us as the head contractor when selecting materials for use on site include: safety; cost; time; speed of installation and availability of product; ease of handling/transporting to site and while on-site; and environmental benefits of products as the project is chasing a 6-star Green Star as-built rating”

“USG Boral’s SHEETROCK® plasterboard should provide us with increased productivity due to the fact it is about 15% lighter than USG Boral’s regular plasterboard. This assists in delivering the product to the various locations within the building, the time it takes to install product and the distribution of material loads in both a stored and fixed scenario.” said Grocon Assistant Project Manager, Cameron Starkey.

In total, approx. 30,000m2 of SHEETROCK® Plasterboard is being supplied to the 480 Queen Street project with USG Boral staff working closely with NAC and Grocon to ensure supplies are delivered to site in a timely manner.

The site is located on one of central Brisbane’s busiest roads, indicating the coordination of deliveries at times when the crane can lift packs of SHEETROCK® off the delivery trucks and directly up to the Preston Decks is critical to site efficiency.

“The delivery of SHEETROCK® Plasterboard from USG Boral to the site are tightly scheduled as we have to book crane time so the packs can be lifted straight off the truck up to the Preston Decks on the relevant floor. Then, our guys unload the packs and distribute them around the floor to where the board will be installed.”

“Our boys like working with USG Boral SHEETROCK®. Fifteen per cent lighter* doesn’t sound like much, but it makes a big difference when they are working overhead installing ceilings as they are on the project. When carrying the board overhead, it doesn’t flex as much and is generally more stable than regular 13mm plasterboard.”

“We also find that the SHEETROCK® board is more rigid than regular plasterboard and we have less breakages, which increases our productivity.”

“Another benefit of SHEETROCK® is how easily it scores and snaps in comparison to 13mm board, it is much cleaner and results in less dust and mess to clean up after cutting.”

“What’s also important to us, particularly as our contract is D and C, is that USG Boral is multi-national, it gives us comfort that they will stand by their product with warranties, on-site inspections and post sales support in general.”

“USG Boral have been great to deal with on this project. They have been reliable and responsive which helps us deliver our obligations according to our contract” said Managing Director of NAC, Danny Simpson.

“USG Boral is committed to delivering the industry’s most innovative and advanced products to our customers. With USG Boral SHEETROCK® Plasterboard, we are delivering what our customers have been asking for” said Frederic de Rougemont, CEO of USG Boral Building Products. “This product redefines the plasterboard marketplace by creating a more productive way to approach wall and ceiling board installation without compromising on time or quality” said Frederic.

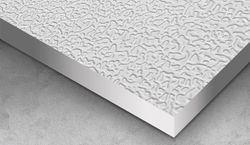

USG Boral’s patented technology and innovative chemistry are key to the creation of the new plasterboard product. USG Boral Sheetrock® Plasterboard features Sag-Defying- Strength™ – which is ideal for ceilings because it is fundamentally reengineered for improved sag resistance and improved strength-to-weight ratio. Sag-Defying Strength™ also helps reduce the chance of damage during handling and installation. And with a consistent core that’s easy to score and snap, this could translate to less waste and potential material cost savings.

- 15% lighter–easier to carry and install*

- A consistent core that’s easier to score and snap*

- Stronger kilogram-for-kilogram*

- Delivers Sag-Defying Strength™

- Available in ceiling boards and wall boards

- Complies with the Building Code of Australia and relevant Australian Standards

USG Boral products are manufactured from a combination of natural gypsum, and paper liner made from 100% reclaimed and recycled paper waste. Plasterboard waste can be reclaimed and recycled into new plasterboard, or reused as soil conditioner.

*Compared to USG Boral’s standard plasterboard.

The opinions expressed by the employees of Grocon and NAC above are the opinions of those third parties and should not be taken to reflect the views or opinions of USG Boral. For more information on SHEETROCK® please visit; www.USGBoral.com/sheetrock