-

PHILIPPINES, ENGLISH

- Contact

- Where to Buy

- Favourites

-

Looking for product documents?

Try our Document Finder

-

Who is Knauf

-

Who is Knauf

-

About Knauf

-

About Us

-

- Careers

-

Contact Us

-

Contact Us

-

- Code Of Conduct

- Supplier Code of Conduct

-

-

Products

-

Products

-

Wall

-

Wall

- Standard Gypsum Boards

Standard Gypsum Board

- Technical Gypsum Boards

Technical Gypsum Board

-

-

Ceilings

-

Ceilings

- Acoustic Panels & Ceiling Tiles

ACOUSTIC PANELS & CEILING TILES

- Vinyl Ceiling Tiles

VINYL CEILING TILES

-

-

Jointing and Finishing

-

Jointing and Finishing

- Premium Jointing

Premium Jointing

- Premium Premix

Premium Premix

- Paper Joint Tape

Paper Joint Tape

- Premium Cornice

Premium Cornice

- Premium Casting

Premium Casting

-

Technical Boards

-

-

Solutions

-

Solutions

-

Commercial

-

Commercial

- Health Care

Health Care

- Education

Education

- Offices

Offices

- Hotel

Hotel

- Retail

Retail

- Entertainment

Entertainment

-

-

Residential

-

Residential

- New Built Residential

New Built Residential

- Repair, Maintainance, Improvement

Repair, Maintainance, Improvement

-

-

USG BORAL EASYFINISH®

-

USG BORAL EASYFINISH®

- USG Boral EasyFinish® Bond System

USG Boral EasyFinish® Bond System

-

USG Boral EasyFinish® Bond System

This system is also known as the “scoop” system, a cement plaster replacement system that is cost efficient, easy to install, and minimizes the chances of cracks.

- USB Boral EasyFinish® Frame System

USB Boral EasyFinish® Frame System

-

USB Boral EasyFinish® Frame System

This system uses metal framing applied as a wall lining, making it especially suitable for reinforced concrete walls or block walls with severe irregularities. It also improves acoustic performance while allowing services to be placed in its cavity.

- USG Boral EasyFinish® Solid System

USG Boral EasyFinish® Solid System

-

USG Boral EasyFinish® Solid System

This system offers two different application methods. EasyTrowel® Application and EasyScoop® Application. These tools provide an easy way to apply the bonding compound in the right thickness, or an innovative solution that eliminates the need to use a mortar-and-sand mix for plastering.

-

-

-

Inspiration

-

Inspiration

-

-

Resources & Tools

-

Resources & Tools

-

CAD Finder

-

CAD Finder | Knauf Philippines

-

- Document Finder

- Lighting & Decoration Guide

-

Acoustic Ceilings e-Estimator

-

Acoustic Ceilings e-Estimator

-

-

plasterboard-materials-estimator

-

Plasterboard Materials Estimator

-

-

-

What's New

-

PHILIPPINES, ENGLISH

- Contact

- Where to Buy

- Favourites

- My Downloads

-

User Profile

User Profile

- Manage Profile

- Logout

-

Looking for product documents?

Try our Document Finder

SUWg4HBaYP13VYhuSncYIghttps://myaccount.knaufapac.com

Royal Children’s Hospital Melbourne

- Past Projects Inspiration

- Architects/ Designers Recommend USG Boral - Testimonials & Reviews

- Royal Children’s Hospital Melbourne

Main Products Used

Echostop™ perforated plasterboard

FIBEROCK® Aqua Tough™

People Involved

Lend Lease Design & Construct

Lend Lease Project Manager

Project Scope

165,000 square metre, seven level structure

Special Factors

13.5mm round hole perforated plasterboard for ceilings. Regular and close communication required between USG Boral engineering and Lend Lease Project Management team with 2100 people involved in the project at its peak.

Need help with a similar project?

Custom Solutions for Royal Children's Hospital

The Royal Children's Hospital (RCH) in Melbourne, Victoria, has seen a mix of new and existing USG Boral Plasterboard products and associated systems integrated throughout the 165,000 square metre, seven level structure. The engineering team at USG Boral Plasterboard worked closely with Lend Lease Project Management Construction and the consultant team during the design and construction phase. This ensured the most economical solutions were adopted to meet project specifications.

-

Innovation inspired by you™.

Glenn Ford, USG Boral Plasterboard's state sales manager, believes the paediatric facility is an example of meeting performance and design outcomes as a result of close working relationships, particularly on site.

"On a job of this scale, where at its peak the project workforce exceeded 2100 people, it's crucial to maintain a physical presence and dialogue with the client to monitor the quality of work undertaken.

"We facilitated weekly walkthroughs with project managers and contractors to assess quality of wall and ceiling installations, compliance to specifications and to provide advice on any technical aspects or concerns," said Ford.

During construction, USG Boral's engineering team used its expertise in fire, structural and acoustic outcomes to enable plasterboard systems to be readily modified to suit site conditions. Structural testing for plasterboard ceilings which needed to accommodate heavy fixtures was carried out, helping the purpose-built facility to house a variety of medical equipment. Technical support for the plasterboard contractors made installation of USG Boral plasterboard systems simple, providing flexible and practical design solutions as required.

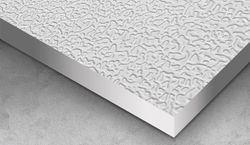

USG Boral Plasterboard's building solutions address a variety of interior applications commonly encountered within hospitals and other healthcare facilities, from fire rated and acoustic systems, to impact and radiation protection linings. USG Boral's FIBEROCK® Aqua Tough™ wall lining, an impact resistant product for high traffic areas, was used extensively at RCH. Offering the impact toughness of masonry, combined with the design and installation convenience of plasterboard, it also helps to minimise the growth of mould.

However, despite the large portfolio of plasterboard solutions, the RCH project also threw up a challenge requiring USG Boral to develop a new product to help the architect achieve acoustic and design objectives.

"The architect specified a product that was not locally available," explains Ford. "We were quickly able to develop and produce a new 13.5mm round hole perforated plasterboard - with the help of our engineering team."

Lend Lease Senior Construction Manager, Bill Alexandrakis, commented, "USG Boral is a preferred supplier and a national alliance partner with a long-standing and successful relationship with Lend Lease. The success at the new RCH is evidence of this."

"USG Boral was involved very early in the procurement, selection and specification process and provided a number of design initiatives that reduced costs and improved on site production. Their management and technical team were very pro-active in ensuring the quality of workmanship was to their and our standards. As an alliance partner, they demonstrated a strong commitment to ESD and our Green Star accreditation.

"USG Boral participated in design reviews and assisted the project consultant team to specify wall systems that met the brief and the acoustic criteria of the project. We were very happy with their service throughout the four-year project, and the technical advantages and innovative design systems they offered helped us achieve our goals and project milestones."