-

PHILIPPINES, ENGLISH

- Contact

- Where to Buy

- Favourites

-

Looking for product documents?

Try our Document Finder

-

Who is Knauf

-

Who is Knauf

-

About Knauf

-

About Us

-

- Careers

-

Contact Us

-

Contact Us

-

- Code Of Conduct

- Supplier Code of Conduct

-

-

Products

-

Products

-

Wall

-

Wall

- Standard Gypsum Boards

Standard Gypsum Board

- Technical Gypsum Boards

Technical Gypsum Board

-

-

Ceilings

-

Ceilings

- Acoustic Panels & Ceiling Tiles

ACOUSTIC PANELS & CEILING TILES

- Vinyl Ceiling Tiles

VINYL CEILING TILES

-

-

Jointing and Finishing

-

Jointing and Finishing

- Premium Jointing

Premium Jointing

- Premium Premix

Premium Premix

- Paper Joint Tape

Paper Joint Tape

- Premium Cornice

Premium Cornice

- Premium Casting

Premium Casting

-

Technical Boards

-

-

Solutions

-

Solutions

-

Commercial

-

Commercial

- Health Care

Health Care

- Education

Education

- Offices

Offices

- Hotel

Hotel

- Retail

Retail

- Entertainment

Entertainment

-

-

Residential

-

Residential

- New Built Residential

New Built Residential

- Repair, Maintainance, Improvement

Repair, Maintainance, Improvement

-

-

USG BORAL EASYFINISH®

-

USG BORAL EASYFINISH®

- USG Boral EasyFinish® Bond System

USG Boral EasyFinish® Bond System

-

USG Boral EasyFinish® Bond System

This system is also known as the “scoop” system, a cement plaster replacement system that is cost efficient, easy to install, and minimizes the chances of cracks.

- USB Boral EasyFinish® Frame System

USB Boral EasyFinish® Frame System

-

USB Boral EasyFinish® Frame System

This system uses metal framing applied as a wall lining, making it especially suitable for reinforced concrete walls or block walls with severe irregularities. It also improves acoustic performance while allowing services to be placed in its cavity.

- USG Boral EasyFinish® Solid System

USG Boral EasyFinish® Solid System

-

USG Boral EasyFinish® Solid System

This system offers two different application methods. EasyTrowel® Application and EasyScoop® Application. These tools provide an easy way to apply the bonding compound in the right thickness, or an innovative solution that eliminates the need to use a mortar-and-sand mix for plastering.

-

-

-

Inspiration

-

Inspiration

-

-

Resources & Tools

-

Resources & Tools

-

CAD Finder

-

CAD Finder | Knauf Philippines

-

- Document Finder

- Lighting & Decoration Guide

-

Acoustic Ceilings e-Estimator

-

Acoustic Ceilings e-Estimator

-

-

plasterboard-materials-estimator

-

Plasterboard Materials Estimator

-

-

-

What's New

-

PHILIPPINES, ENGLISH

- Contact

- Where to Buy

- Favourites

- My Downloads

-

User Profile

User Profile

- Manage Profile

- Logout

-

Looking for product documents?

Try our Document Finder

SUWg4HBaYP13VYhuSncYIghttps://myaccount.knaufapac.com

Gold Coast University Hospital Expansion

Main Products Used

FIBEROCK® Aqua Tough™ Interior Panels

People Involved

Architect: GCUH Architecture (PDT, Silver Thomas Hanley & Hassell Architects)

Interior Contractors: NWCI Commercial Interiors Newcastle Commercial Interiors TAF Group Superior Walls and Ceilings

Managing Contractor: Lend Lease

Project Scope

550,000m2

Special Factors

One of Queensland’s largest clinical teaching and research facilities, providing specialised health services that meet the needs of patients and the learning requirements of students.

Project Cost

$1.76 Billion

Need help with a similar project?

Gold Coast University Hospital

The $1.76 billion, 750 bed Gold Coast University Hospital in Queensland, Australia, is part of a major expansion of health services for the Gold Coast community, with Lend Lease working in partnership with Queensland Health as the Stage One Managing Contractor.

The hospital is one of Queensland’s largest clinical teaching and research facilities, providing specialised health services to meet the needs of patients and the learning requirements of students. At the time of construction, it was one of the largest public health infrastructure projects in Australia. The facility is State Government owned and operated and forms part of the Government’s plans for a ‘Health and Knowledge Precinct’ for the area.

The hospital is a vital component in Queensland Health’s vision to deliver state-of-the-art health facilities and services that cater for the extraordinary population growth in South East Queensland.

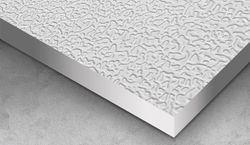

With increased resistance to indentation and penetration, FIBEROCK® Aqua Tough™ interior panels outperform speciality plasterboard and fibre cement panels. They are suitable for use on walls, ceilings, and exterior dry soffit applications, offering abuse, moisture, mould and fire-resistance.

USG Boral FIBEROCK® was the wallboard of choice for this project as it delivered unmatched performance in the areas of impact, acoustics, fire, moisture and mould control.

These high-performance panels derive both strength and water resistance from their uniform composition. As a result, they won’t lose their strength when cut. They are ideal for wet areas, because their panel surface will not delaminate when wet. They provide a smooth, paintable surface that can also be finished with ceramic tiles. One type of panel can be used for an entire room, simplifying design and installation, shortening job schedules and lowering in-place costs. They are made from 95% recycled materials, an environmentally friendly option for use in sustainable building construction.

“FIBEROCK® Aqua Tough™ provides us with a full system solution across both wet and dry areas. It is high impact, mould and wet area resistant and will outlast anything on the market. It has the same buildability in wet and dry areas and one product means less manhandling; that’s what sold it to me. It does it all.” Interior Contractor Neville Berry - Project Manager Superior Walls and Ceilings.

“For any medical buildings and office projects the first thing I would say is – use FIBEROCK®”. “Because FIBEROCK® can be used in both wet and dry areas the cost is actually less than plasterboard and fibre cement products. It is a superior product due to the nature of the composite board, it is easy to work with, it does not crack unlike fibre cement products and when impacted does not get holes unlike plasterboard products. This means there are no areas for micros such as superbugs to reside, and for hospitals this is critical. It also means that we do not have to keep going back in to repair holes and cracks. This saves considerable time and money in after-build costs"."The product has high acoustic and fire rating statistics, and because it can be used across wet and dry areas, there is less room for error in a job. FIBEROCK® is easy to work with, and the composition of the board means that we can drill and screw lightweight attachments directly to the board. Because there is no paper lining and the ends of the board can be recessed, we can achieve a homogeneous surface finish which is perfect for long corridors with glancing light.” Managing Contractor, Paul Langhome – Project Manager Lend Lease.

Click here to read our Whitepaper on designing versatile healthcare facilities.